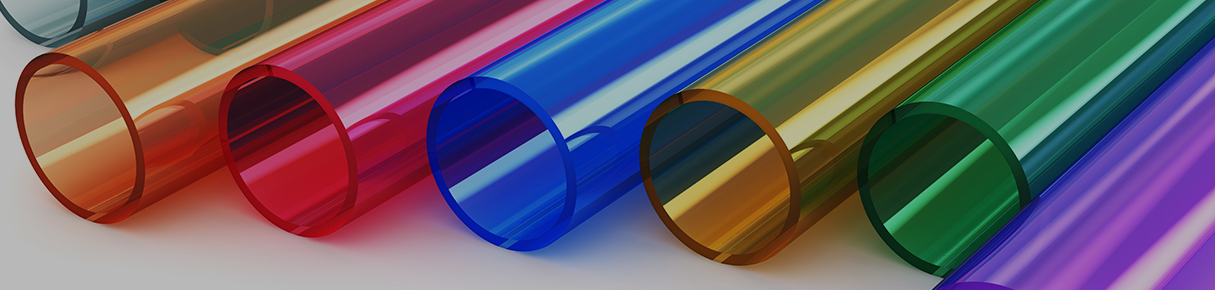

Polyurethane Tube

Is used in many industries with a variety of applications, polyurethane tube, has several diameters, lengths, colours etcetera. To ensure complete functionality of what is available; custom formulations are required to produce tube for the required application it is intended.

Polyurethane Tube Sizes

Our polyurethane tubes are custom moulded as ordered. The outer and inner diameters can be infinitely varied depending on the requirement. A standard length is 1200mm! However smaller internal sizes may need be shorter achieve concentricity. large sizes may be ordered in shorter lengths as well. Polyurethane tubes are available in a wide range of sizes.

For quantities of short tubes of washers or sleeves, custom machining may be required.

A limited stock of some tube sizes is available.

Polyurethane Tubing

Polyurethane is recognised as an effective flexible application in industry.

It is the preferred alternative to metal, rubber or plastic.

Polyurethane has superior properties in these areas.

- Abrasion and impact resistance

Has superior abrasion and impact resistance to rubber and plastic.

It is lightweight compared to metal or aluminium. - Resilience

Is significant; polyurethane will rebound back to its original shape far beyond that of metals or plastics. - Resistance

Polyurethane is resistant to petrochemical solvents, oil and ozone’s.

Stable at low temperatures. - Noise reduction

It reduces noise migration in mechanical operations. - Load bearing

Polyurethane is a higher density material. Rubbers, plastics/nylon polyethylene etcetera are low density materials.

Its superior load bearing is dew to the compression modulus of the material.

Rubber has a low compression modulus.

Polyurethane products are superior in application many areas when compared to using other convention materials commonly.

Contact support@polynyl.com or call us on 03 9459 1708 and our team will arrange a specification for the product or service that you may require.